Cut Charts for Hypertherm 65/85/105® SYNC

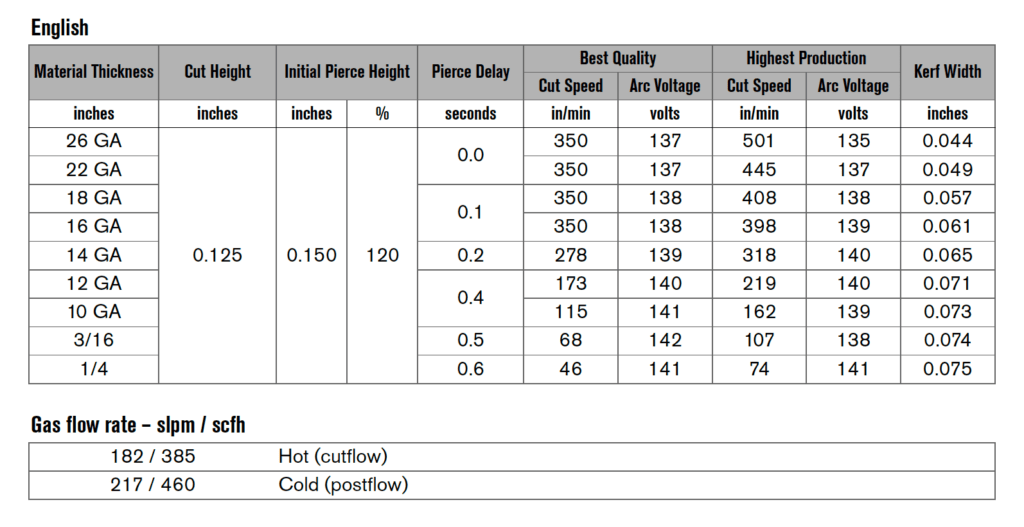

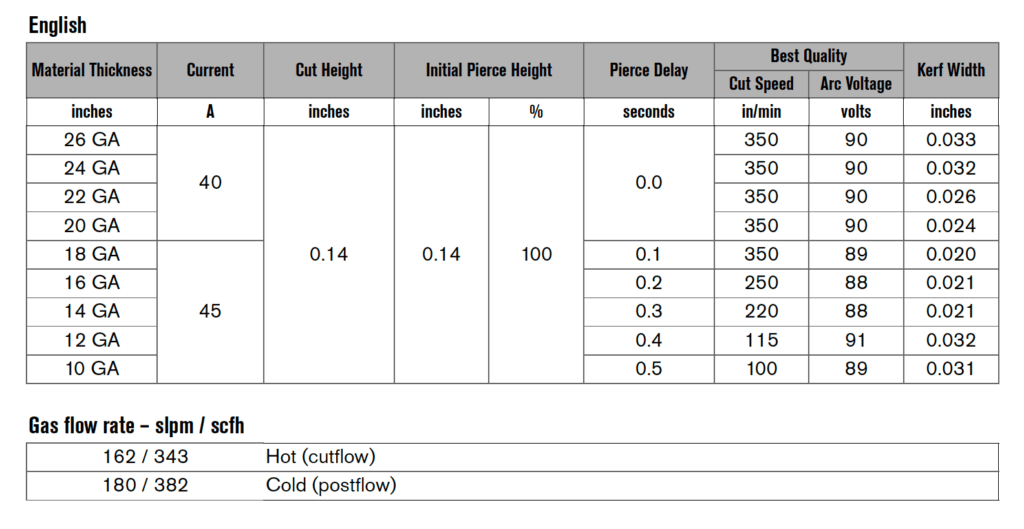

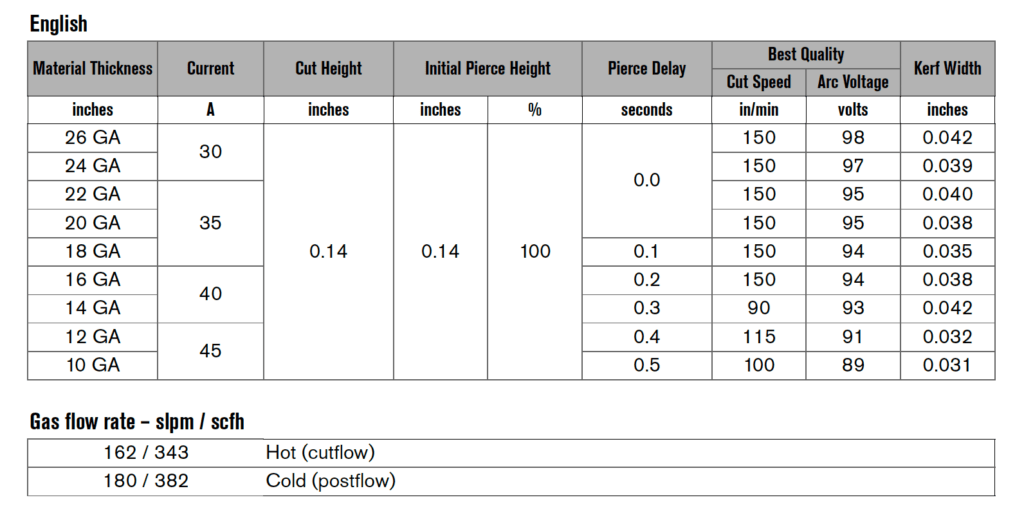

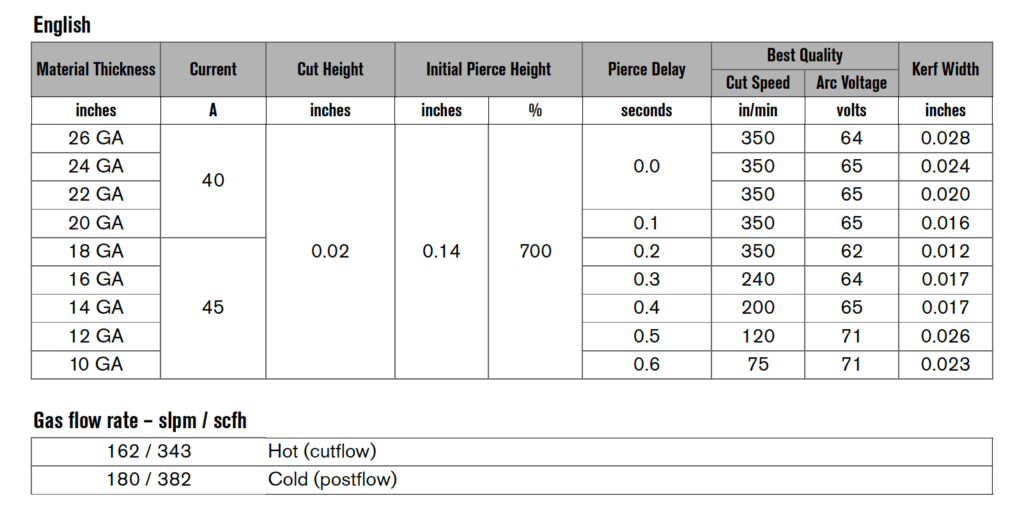

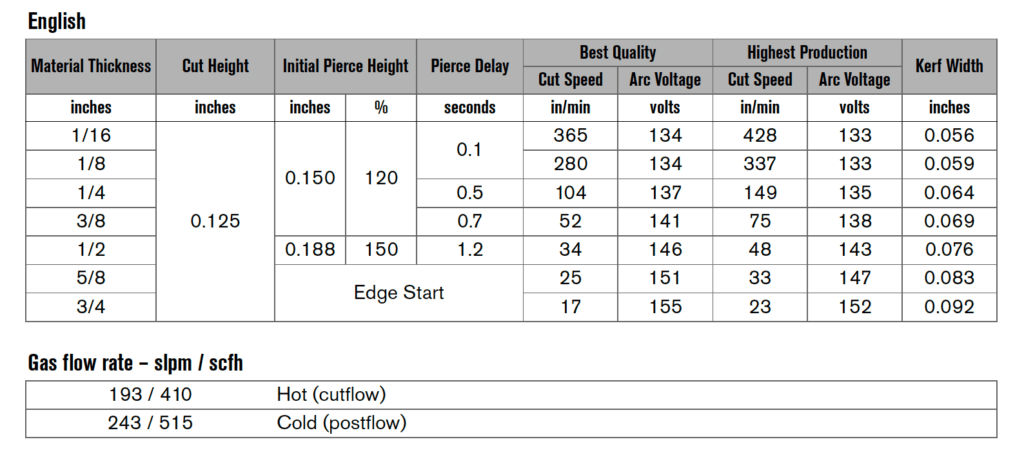

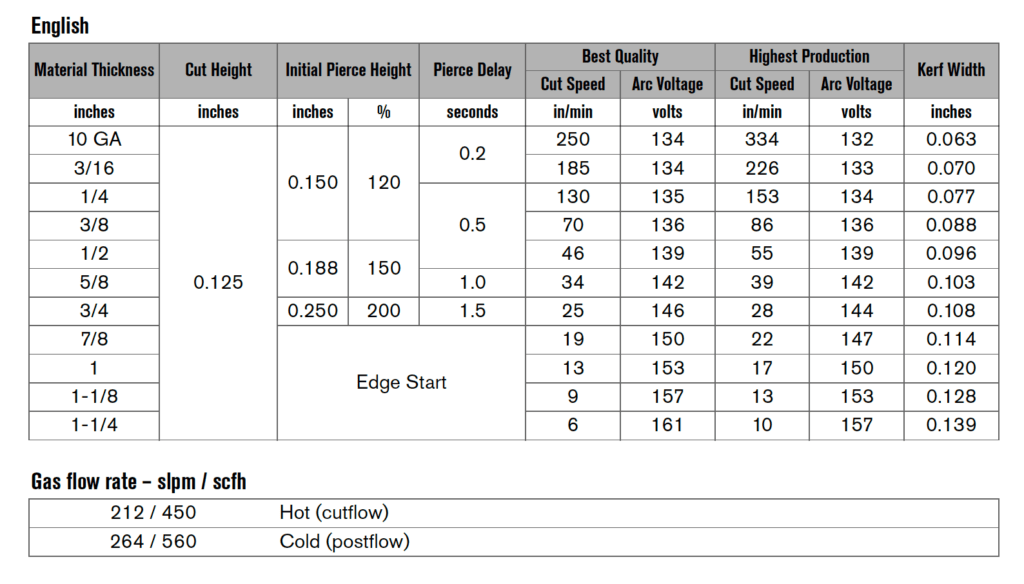

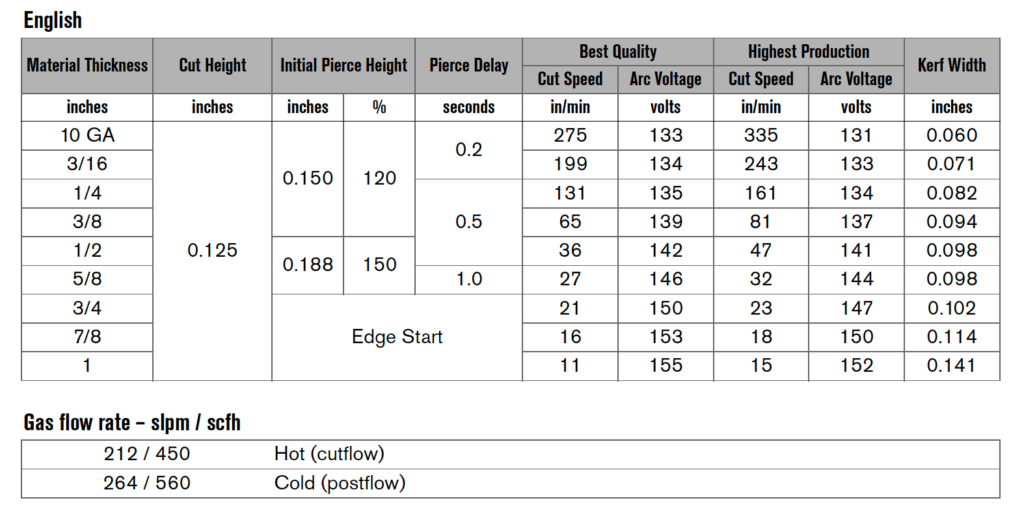

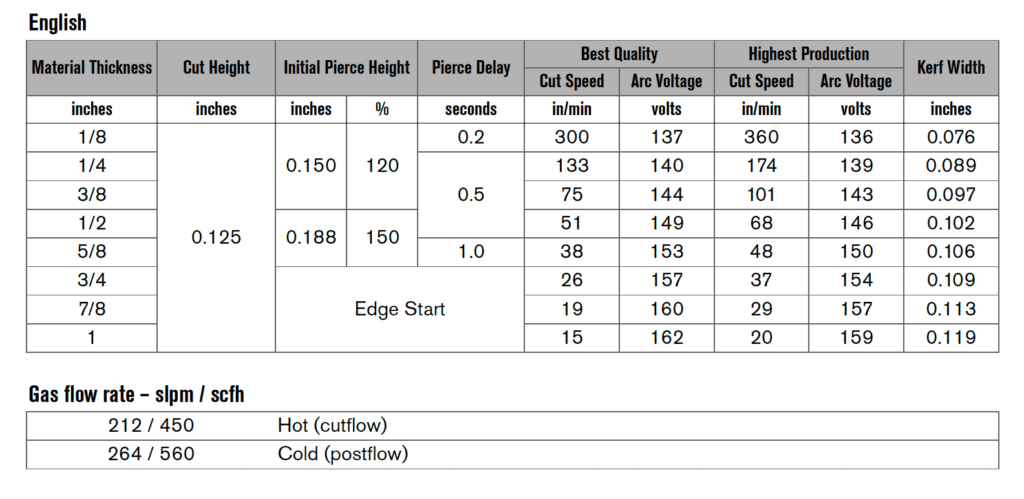

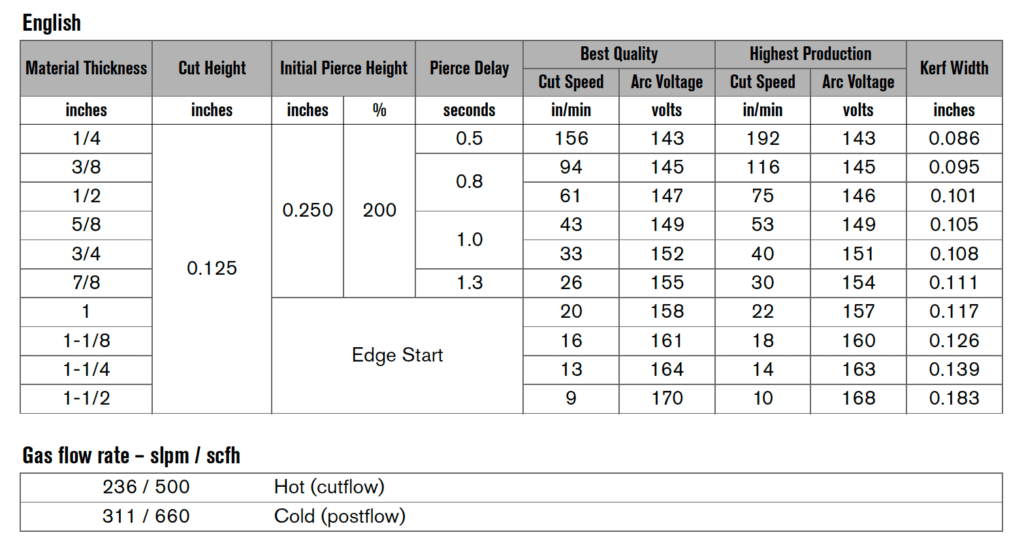

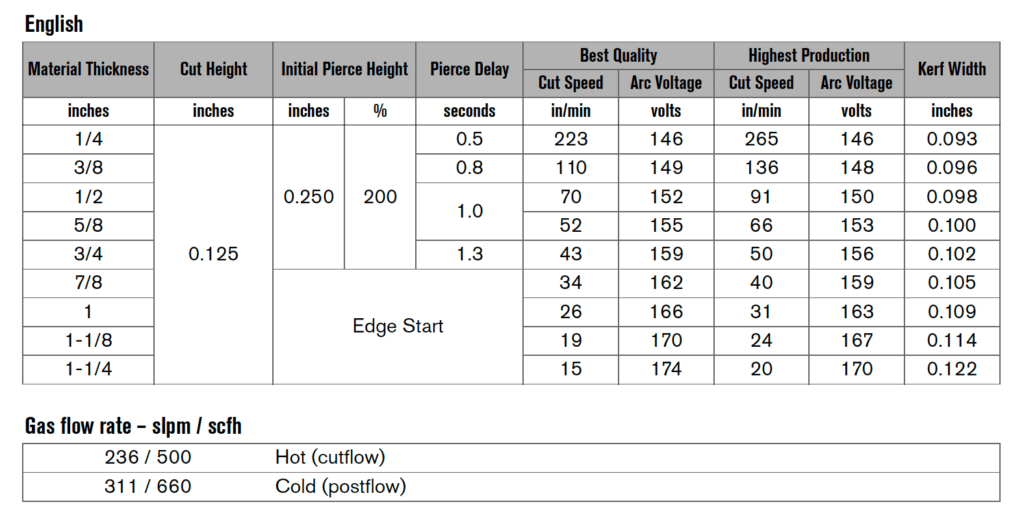

In FineCut charts, the amperage for each thickness is included in the cut chart. This guide includes high-speed and low-speed charts. High-speed settings can give better cut quality and less dross at some thicknesses, if the cutting table lets you cut at those settings. Each cut chart lists hot and cold gas flow rates.

slpm = Standard liter per minute.

scfh = Standard cubic feet per hour.

Hot (cutflow) = Plasma arc is on, and there is a steady flow of gas while cutting.

Cold (postflow) = Plasma arc is off, and there is a steady flow of gas for several seconds after the cut completes. This flow rate also applies for gas test mode.

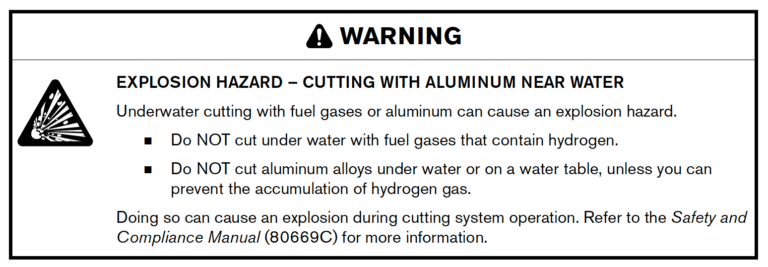

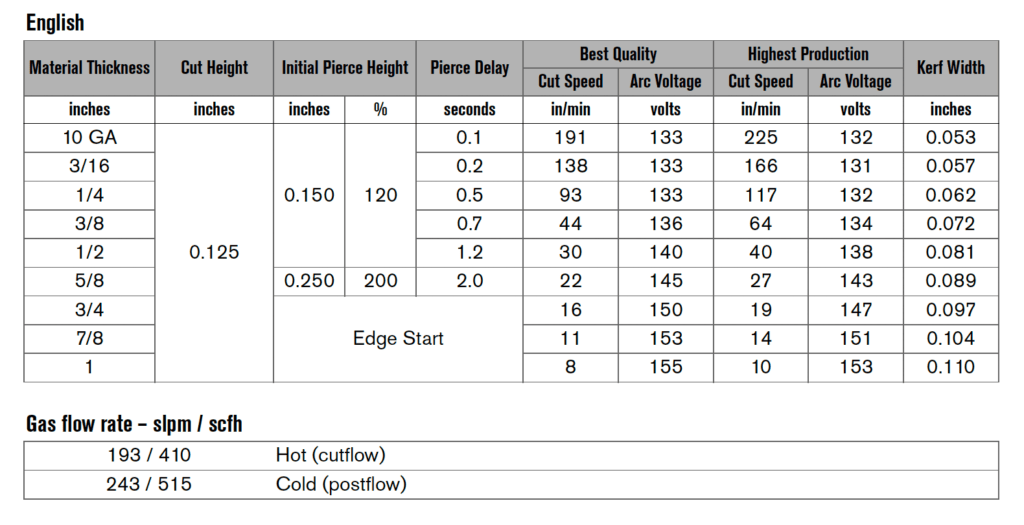

Cut Height = Distance between the tip of the cartridge and the workpiece during cutting.

Initial Pierce Height = Distance between the tip of the cartridge and the workpiece when the torch is fired, prior to descending to the cut height.

Pierce Delay = Length of time the plasma arc remains stationary at the pierce height while it cuts through the workpiece.

Best Quality (Cut Speed and Arc Voltage*) = Settings that provide the starting point for finding the best cut quality (best angle, least dross, best cut-surface finish). Adjust the speed for your application and cutting system to get the desired result.

Highest Production (Cut Speed and Arc Voltage*) = Settings that increase cut speeds 20% – 30%. These speeds give an increased number of cut parts but not necessarily the best possible cut quality.

Kerf Width = Width of material removed by the cutting process. The kerf widths are for reference only. Hypertherm got them using the “Best Quality” settings. Differences between installations and material composition can cause actual results to vary from those shown in the tables. * For information on how to use arc voltage to control cut height, refer to the Powermax65/85/105 SYNC Mechanized Cutting Guide (810480).

45A

Mild Steel 45A – Cartridge 428925

Mild Steel 45A – Fine Cut Cartridge 428926 (HIGH SPEED)

Mild Steel 45A – Fine Cut Cartridge 428926 (LOW SPEED)

Stainless Steel 45A – Cartridge 428925

Stainless Steel 45A – Fine Cut Cartridge 428926 (HIGH SPEED)

Stainless Steel 45A – Fine Cut Cartridge 428926 (LOW SPEED)

Aluminum 45A – Cartridge 428925

(Hypertherm® does not recommend cutting aluminum with FineCut cartridges)

65A

Mild Steel 65A – Cartridge 428930

Stainless Steel 65A – Cartridge 428930

Aluminum 65A – Cartridge 428930

(Hypertherm® does not recommend cutting aluminum with FineCut cartridges)

85A

Mild Steel 85A – Cartridge 428934

Stainless Steel 85A – Cartridge 428934

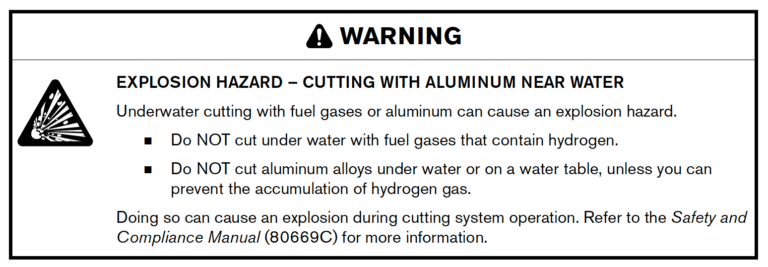

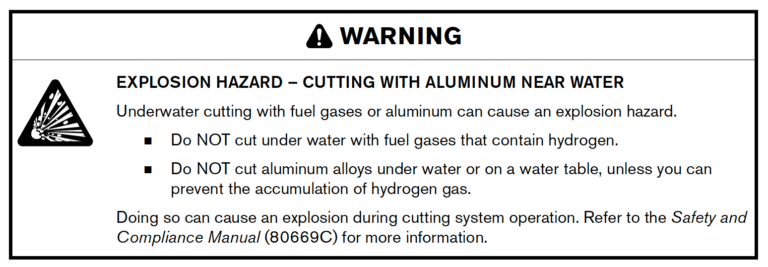

Aluminum 85A – Cartridge 428934

(Hypertherm® does not recommend cutting aluminum with FineCut cartridges)

105A

Mild Steel 105A – Cartridge 428936

Stainless Steel 105A – Cartridge 428936

Aluminum 105A – Cartridge 428936

(Hypertherm® does not recommend cutting aluminum with FineCut cartridges)